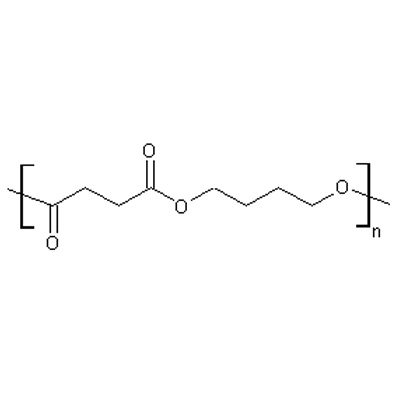

Characteristics of PBS

PBS is a kind of white crystalline polymers, its basic mechanical properties is similar to conventional plastics (PE \ PP), it is completely biodegradable and has good biocompatibility.

Appearance: polymer of white crystal

Density:1.26

Melting point:115℃

Crystallinity:30-40%

Tension yield:600%

Yield strength:35MPa

Strength at break:28MPa

Mechanical property: similar to traditional plastics (PE&PP)

Advantages of PBS

Excellent molding processability: this is the most important factor for degradable plastics application in real life. It can be molded for plastics of any kind;

Excellent me chanical property: Its mechanical property which stand between PE and PP can research the requirement of plastics in wild use;

Good biodegradability: By the action of compost, biodegradability ratio hits 90% with 90 days;

Strong resistance to heat: The deformation temperature is near100 ℃and cover100 ℃after modification. So it can be used for packaging, such as icy and hot drink boxes, food bags;

Wild application: Due to its wild application in packaging, disposable apparatus, agricultural and medical materials, it is the fundamental solution to environmental pollution caused by traditional plastics.

Decomposition of PBS

Decomposition of PBS goes through two stages. Firstly, the decomposition occurs from outside to inside by the interaction with microform, then diatomic alcohol and blending of low molecular weight polymer ( lower than polymer) results from that process.

The next step is entire decomposing process, PBS can either be biodegraded into carbon dioxide and water with great air permeability or into carbon diocide and methane with poor air permeability.

Quality Index of PBS

|

Test Item

|

Condition

|

Units

|

Test Result

|

|

Blister molding products

ART NO. AJL0618A

|

Ingection molding products

ART NO. AJL0618B

|

Blow molding products

ART NO. AJL0618C

|

|

Relative density

|

25℃

|

|

1.26

|

1.26

|

1.26

|

|

Melt-flow-index

|

190℃/2.16kg

|

g/10min

|

≤15

|

≤20

|

≤10

|

|

Heat –deflection-temperature

|

0.455MPa

|

℃

|

89

|

89

|

89

|

|

Yield strength

|

Tensile speed:2in/min

|

MPa

|

35

|

36

|

33

|

|

Strength at break

|

|

MPa

|

28

|

28

|

27

|

|

Elongation at break

|

|

%

|

200

|

100

|

500

|

|

Flexural strength

|

Flexural speed:0.2in/min

|

MPa

|

34

|

30

|

28

|

|

Flexural modulus

|

≤

|

MPa

|

600

|

650

|

580

|

|

Impact strength

|

Notched A

|

J/a

|

110

|

94

|

130

|

|

Drying shringage

|

|

%

|

≤0.1

|

≤0.1

|

≤0.1

|

【Package and storage】:

Shelf life: valid for 12 months (It is stable in normal storage and use, it only Degraded when it exposes microbial in the condition of compost and soil).

Package: Paper compound bag, 25kg/ bag

Storage: It should be stored in dry place at room temperature

Transportation: It should avoid the sun and rain during transportation, it should be loaded and unloaded carefully, it can’t be transported mixed with poisonous or other contaminated goods.

Application:

PBS polyester application includes injection molding, blow molding, blister and foming;

Packaging materials: garbage bag, clothes bag, label, bottle, tray and bracket, clapboard;

Disposable materials: fast food box, fork and knife, disposable cup;

Agricultural materials: composite film;

Construction and landscaping materials: landscaping peg adhesive plaster, lawn net, plant cover net,

Fishery materials: fishing bait bag, cushion materials, fishing net, fishing belt and line;

Daily necessary commodities: handbag, pens of all kinds, card, baby diaper, senitary products;

Medical materials: medicine carrier, injector and others.